Rise of 2D: GS1 Sunrise

The Next Generation of Product Identification: Preparing for GS1 Sunrise 2027

A major transformation is coming to manufacturing identification systems. This evolution is being driven by an industry-wide mandate known as the GS1 Sunrise 2027 initiative, which represents the most significant change to product identification standards in decades.

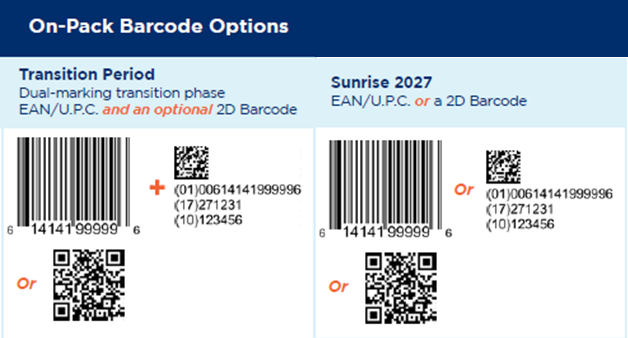

The GS1 Sunrise 2027 Initiative is a global project aimed at transitioning from 1D EAN (vertical lines) barcodes to 2D barcodes (QR codes).

Why the change? The traditional barcode just isn’t enough anymore. Consumers, regulators, and supply chains all demand more transparency, traceability, and data from the packaging throughout their lifecycle.

The new 2D barcodes will unlock a new level of functionality for the retailer and consumer:

- Detailed product info/data storage (ingredients, allergens, sourcing)

- Web engagement and marketing

- Inventory & supply chain management/improved traceability

- Product authentication & recall readiness

- Support for sustainability and ethical sourcing

- High readability

Four steps to begin transitioning from 1D to 2D barcodes

Determine product information to encode: First, decide what information you want to include in your barcodes. Compared to 1D codes, 2D codes can store large amounts of data including lot codes, expiration dates, links, etc.

Define the labelling strategy: Manufacturers need to choose between static pre-printed labels or dynamic labels, which are in-line digital and on-demand printing labels. For data with high variability, dynamic codes are often recommended.

Meet code quality standards: To comply with new GS1 and ISO standards, maintaining high code quality is a must. To help monitor, track, and validate barcode quality, it’s helpful to integrate barcode grading tools into operations.

- Since more information can be encoded on 2D codes than the old 1D codes, many brands will choose to print the 2D codes on their labels as part of the production process.

- These printed codes must meet both “code quality” and “print quality” requirements like positioning, angle, uniformity, and more.

- New quality steps must be put in place to address this new process – which is where machine vision-based automated inspection comes in.

- Even when using the new 2D codes, manufacturers also must print separate identifying text codes on labels and verify those against the requirements as well.

- A GS1 Digital link is an encoding method with a specific syntax that enables product information to be digitised and accessed via a web link. The pages behind the web link can contain both consumer-focused and supply-chain partner-focused information.

- Using this method, if information changes, it’s managed on the back end, and the code doesn’t need to change – providing greater flexibility and reducing the need to update physical labels when product details, regulatory information, or supply chain requirements evolve over time. A supply chain partner can scan the code and get relevant product information such as lot code, expiration date, etc., which helps them manage their inventory more efficiently.

Choosing a machine vision partner: Selecting the right technology partner is critical to a successful transition. Working with a vendor that offers 2D barcode solutions will help ensure compatibility across production lines, simplify troubleshooting, and streamline training. Look for partners with GS1 expertise who provide clear paths from existing 1D systems to reduce operational disruption while offering scalable adaptable solutions.

Cutting costs with machine vision

The transition to 2D barcodes as part of the GS1 Sunrise 2027 initiative brings with it several considerations related to costs and savings. It’s important to consider expenses when implementing machine vision systems and high-speed 2D barcode readers to replace readers that do not support 2D codes.

Manufacturers can save costs significantly with the optimised production that machine vision offers. A great example is using digital on-demand code printing for quicker production, which is more efficient and cost-effective than pre-printed labels.

Time-to-market

Transitioning to 2D barcodes can also significantly accelerate time-to-market. 2D codes have much more readability – meaning that even if a code is damaged, it can still be decoded more than a damaged 1D code.

This helps reduce delays in production, helping products move through the supply chain more swiftly. This efficiency is crucial in fast-paced manufacturing environments where time is of the essence.

Additionally, manufacturers can get more detailed product information in a single scan which further streamlines operations and reduces the need for human intervention. This efficiency not only optimizes operations but also helps manufacturers adapt seamlessly to upcoming industry standards.

By preparing for the GS1 Sunrise 2027 initiative now, manufacturers can leverage Cognex’s AI-powered tools and solutions to ensure a smooth transition.

The implementation date is creeping up on us and manufacturers and contract packers need to be ready. Acrovision’s Validator solution’s have been developed just for applications like this. Please reach out to us if you would like to discuss the changes and what they could mean to you.

Challenges of transitioning to 2D barcodes

With the transition to 2D barcodes come several challenges manufacturers must be aware of. Some of these challenges include:

- Changes to existing processes: Operations that are currently using 1D codes might need to undergo changes to seamlessly transition to the new standard.

- New quality control measures: It’s important for new quality control rules, procedures, and measures to be established clearly for the new transition.

The main reason for more quality control rules and procedures is that manufacturers might want to print 2D codes on demand as a part of the production process instead of buying labels with pre-printed codes on them.

- Barcode printing and readability: Making sure that 2D barcodes are printed, scanned, read, and interpreted correctly is key for systems that will depend on 2D barcodes.

- Cost and expenses: Manufacturers will need to consider expenses such as:

Purchasing high-speed 2D image-based barcode readers to replace current barcode readers without 2D code support

Redesigning labels for new 2D codes

Using digital on-demand code printing for quicker production. It’s more efficient and cost-effective to reprogram the label printer for new labels than to keep pre-printed labels.

The shift has already begun. The new technology is being tested in 48 countries across the world, representing 88% of the world’s GDP.