In-Sight 3800 Line Scan Series

Unmatched accuracy and speed for complex manufacturing inspections

The In-Sight 3800 Line Scan is a high-performance, AI-enabled vision system engineered for precision inspection in high-throughput manufacturing environments. Featuring high-resolution line scan imaging and ultra-fast onboard processing, it reliably detects the smallest features and defects at production line speeds, making it ideal for continuous web and surface inspection applications.

The vision system excels in performing detailed inspections on continuous webs, cylindrical surfaces, large parts and parts with complex shapes and patterns.

Key Features

AI Capabilities: Improve quality control with AI-powered defect detection

High-Resolution Imaging: Capture every detail to ensure product quality and reduce the risk of costly errors

High-Speed Processing: Achieve high throughput with lightning-fast image acquisition and tool processing

Fully Embedded Solution: Simplify integration and operation with a compact, space-saving design, no PC required

Application Examples

From detecting defects on continuous webs to inspecting cylindrical surfaces and complex patterns, the In-Sight 3800 Line Scan solves a range of factory automation applications, while delivering high performance at the fastest speeds.

Optical character recognition (OCR): Extract and read text, such as lot codes and expiry dates, from rotating or curved surfaces for accurate product tracking and compliance.

Defect detection: Identify defects on wide-format materials, ensuring high-quality standards for printed media and other substrates.

Presence/absence detection: Verify the presence or absence of key features across multiple regions on large objects to ensure proper assembly.

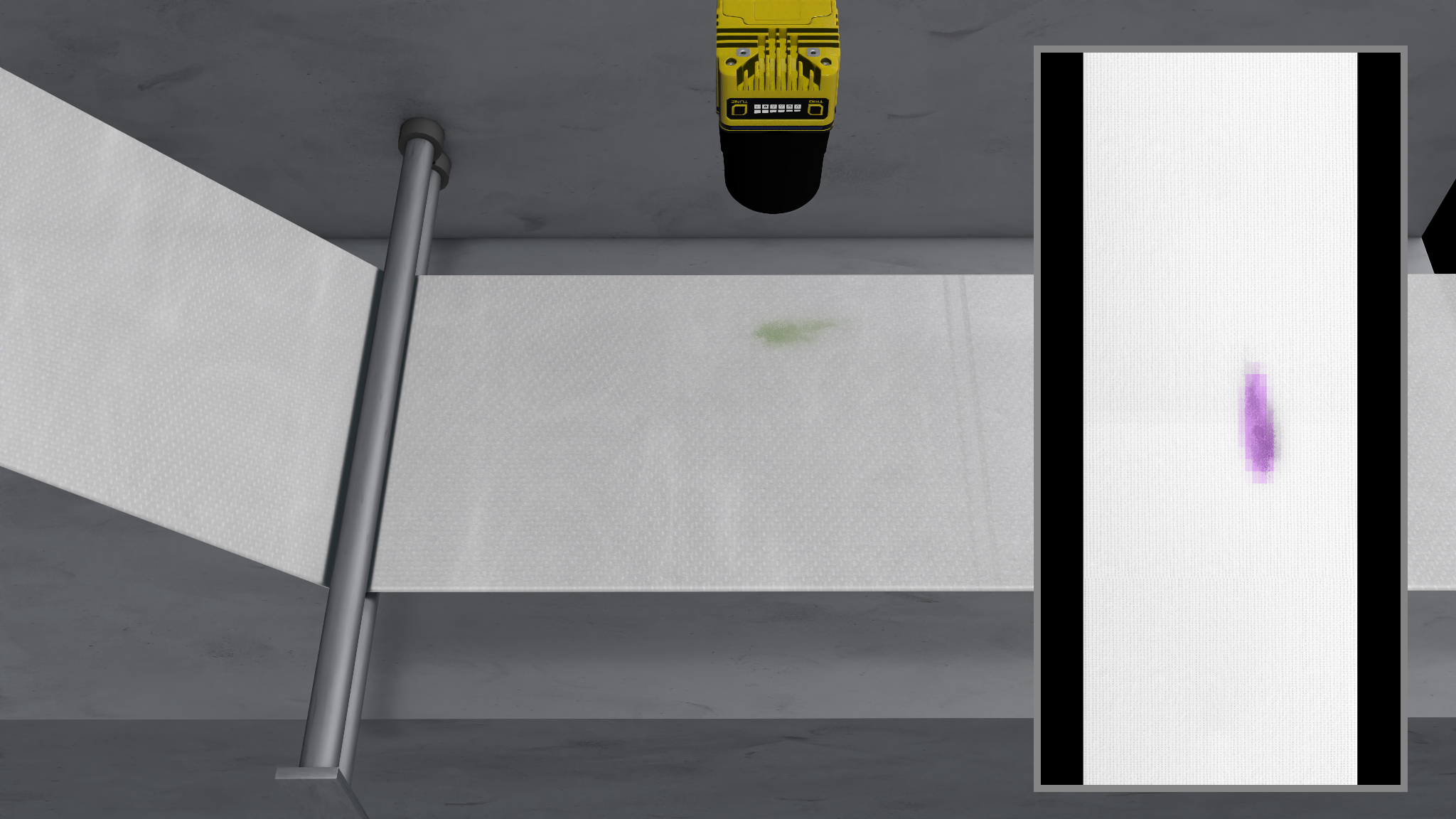

Continuous web inspection: Detect coating voids on continuous web materials to find and correct quality issues during the manufacturing process.

Barcode reading: Accurately decode barcodes on large parts for reliable tracking and traceability throughout production.

Measurement: Unwrap and measure circular or curved parts, ensuring precise dimensions for proper functionality and fit.

Line Scan vs. Area Scan Technology: Choosing the right solution for your application

Elevate quality control with image overlap technology

The In-Sight 3800 Line Scan captures overlapping sections of objects during inspections for complete coverage and more detailed images.

- Improved Accuracy: Overlapping images ensure every part of the object is inspected, minimising missed defects.

- Seamless Inspection: Ideal for high-speed production lines, ensuring no areas are skipped due to fast movement.

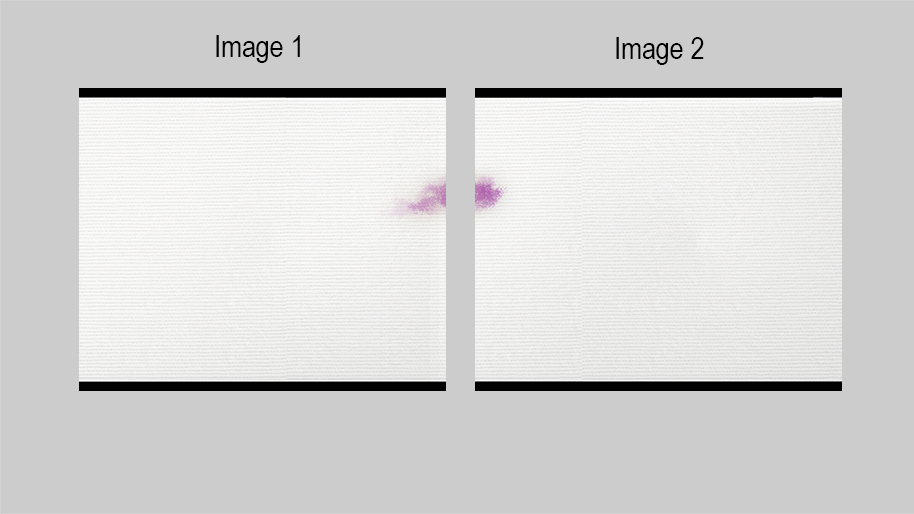

Without Overlap: Defects or features can be split between two images, with gaps in between them.

With Overlap: Defects or features are never split between two images, and no gaps in coverage.

Complete vision toolset solves tasks of any complexity

The In-Sight 3800 Line Scan combines AI-based vision tools with traditional rule-based algorithms in a unified system, offering the flexibility to address a broad spectrum of error-proofing applications. Tools can be deployed independently for straightforward inspections or integrated for solving complex automation tasks with greater precision and adaptability.

Segmentation: Extracts defect, regions and objects from complex parts and backgrounds.

Classification: Detect and sort parts based on multiple features or characteristics.

Optical Character Recognition (OCR): Read characters on reflective, low-contrast and non-flat surfaces, including multi-line text.

Rule-based vision tools

The In-Sight 3800 Line Scan is also embedded with an extensive library of industry-proven traditional vision tools and algorithms including: Measure Distance, Pixel Count, Count Patterns, Math and Logic Tools, and more.

For more information about how the In-Sight 3800 Line Scan can help with your application,