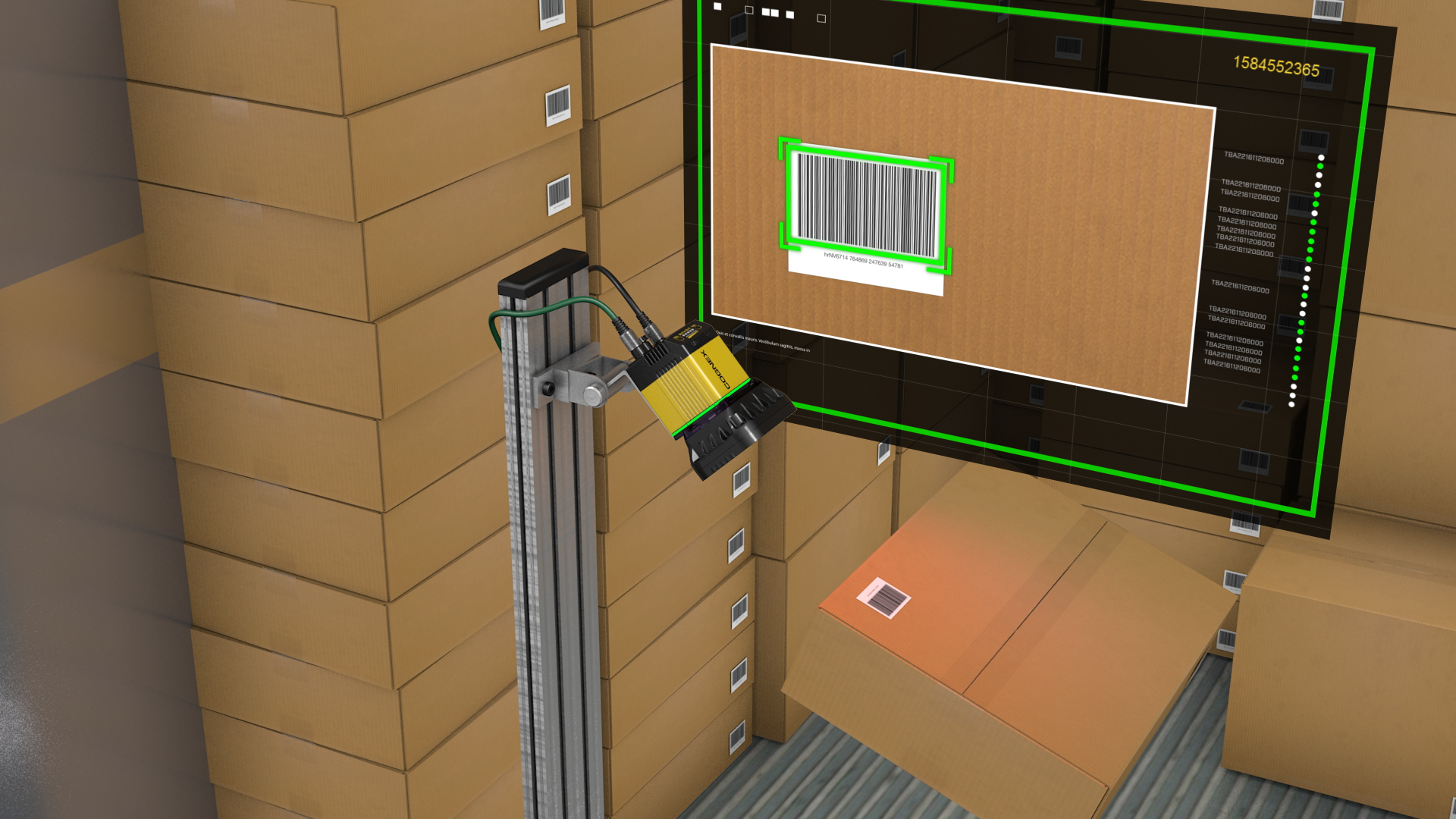

Outbound Scanning

Load outbound trucks faster while increasing traceability and reducing manual handling

Retail distributors and fulfillment facilities are seeking ways to improve traceability from the inbound dock door to the outbound dock door. To achieve “zero loss” of goods as they travel into and through a facility, management teams are becoming increasingly focused on quality of operations and asset management (minimizing loss) so verifying what goes on the outbound truck is more important than ever. In many organizations, operational methods rely on ship sorter accuracy to ensure the right products are loaded on trucks. However, this approach does not always meet loss objectives. Packages get lost, stolen, or get put on the wrong ship lane. For products that make it through the sorter, incorrect sorting can occur due to poor code quality and the scanning system’s inability to read the codes. It is not uncommon for distribution centers to lose several dozen packages per day and tens of thousands over a year. In addition to internal costs, customer expectation and brand reputation are negatively impacted when products are not delivered on time or at all.

Retail distributors and fulfillment facilities are seeking ways to improve traceability from the inbound dock door to the outbound dock door. To achieve “zero loss” of goods as they travel into and through a facility, management teams are becoming increasingly focused on quality of operations and asset management (minimizing loss) so verifying what goes on the outbound truck is more important than ever. In many organizations, operational methods rely on ship sorter accuracy to ensure the right products are loaded on trucks. However, this approach does not always meet loss objectives. Packages get lost, stolen, or get put on the wrong ship lane. For products that make it through the sorter, incorrect sorting can occur due to poor code quality and the scanning system’s inability to read the codes. It is not uncommon for distribution centers to lose several dozen packages per day and tens of thousands over a year. In addition to internal costs, customer expectation and brand reputation are negatively impacted when products are not delivered on time or at all.

Many companies use hand scanners as a basic point of traceability or nothing at all at the dock door. This causes unwanted delays as operators need to take extra time to pick up a scanner, scan a box, put the scanner down, and load the box onto the truck.