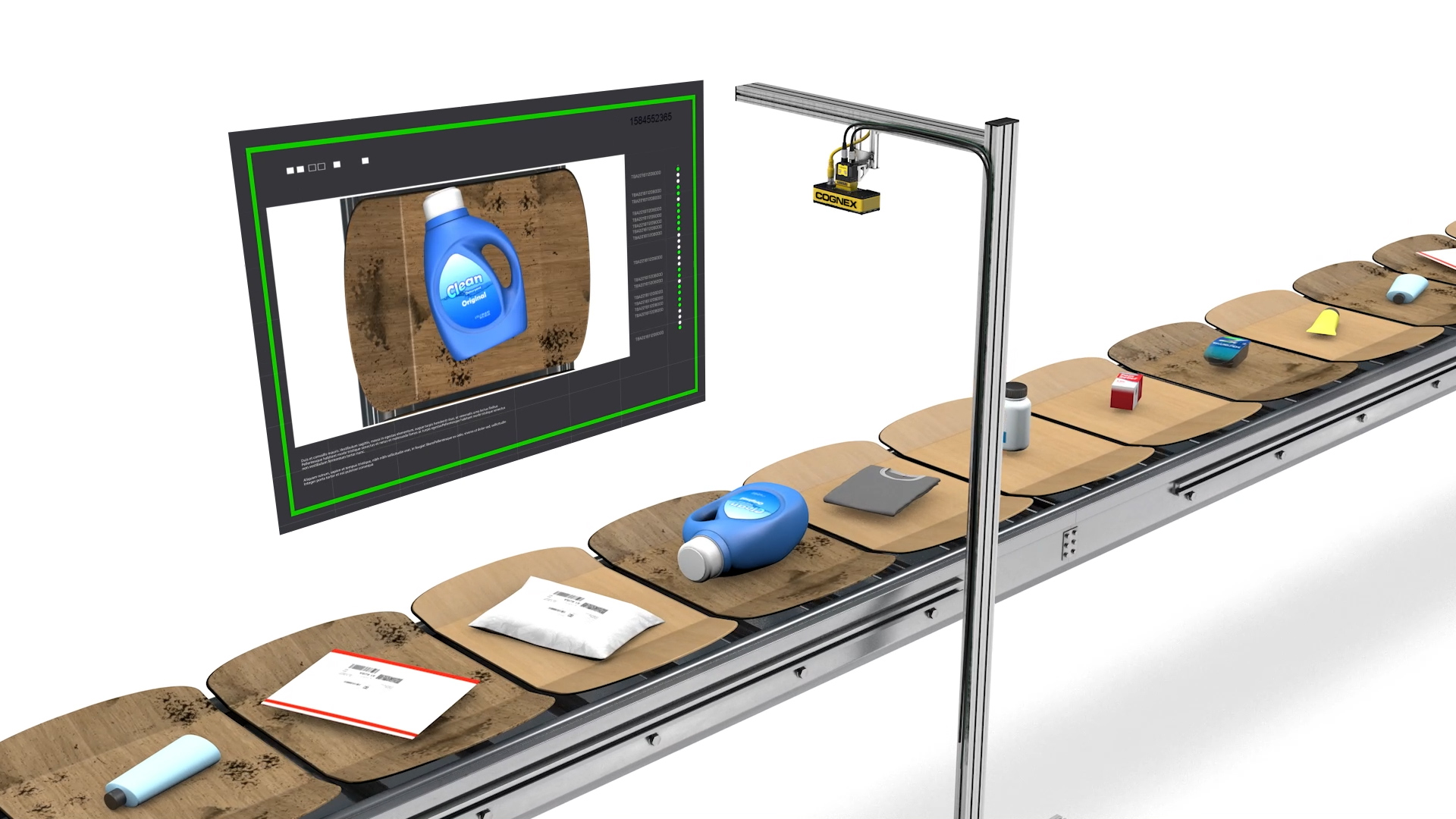

Item Detection

Improve traceability and decrease product loss during the induction process

Ecommerce fulfillment and retail distribution facilities need to accurately induct and sort orders and inventory to final shipment locations. Sorting process must be highly efficient and able to detect and prevent errors that could cause lost product or sorter downtime. Sorters wear down, and accumulate dust, dirt, and labels. Under these conditions, traditional solutions often fail and are expensive to maintain. Some warehouses employ specific staff just to manually tweak, clean, and monitor the sorter. Additionally, existing solutions require custom programming or only work for specific sorter types.

Ecommerce fulfillment and retail distribution facilities need to accurately induct and sort orders and inventory to final shipment locations. Sorting process must be highly efficient and able to detect and prevent errors that could cause lost product or sorter downtime. Sorters wear down, and accumulate dust, dirt, and labels. Under these conditions, traditional solutions often fail and are expensive to maintain. Some warehouses employ specific staff just to manually tweak, clean, and monitor the sorter. Additionally, existing solutions require custom programming or only work for specific sorter types.

Processing issues, such as products hanging over a tray, can result in products falling off the sorter. In these cases, customers will not receive the product and the warehouse will have an inaccurate count of their inventory. Without reliable tray occupation data, induct automation can provide wrong or double counts leading to low order accuracy.