Acrotrace

Acrovision’s turnkey solution comprising a complete system of data capturing relevant barcodes and integrated data aggregation software.

Acrovision's Operator Guidance Made Easy

Acrotrace

Acrovision helps Waymade meet their supply chain efficiency requirements with their Mobile Aggregration Workstation.

Waymade is a global speciality pharmaceutical business focusing on product development, licensing and commercialisation of generic and niche medicines. Waymade’s utilised serialisation platforms are services that enable real-time visibility, collaboration and supply of serialisation data to ensure their pharmaceutical products meet market regulations for FMD (Fraudulent Medicines Directive).

Serialisation is a part of the FMD with some countries also requiring aggregation as part of their product regulations. Aggregation being a process that creates a parent and child relationship between different packaging levels as required for the specific market. Waymade’s requirements specifically being for individual product pack serial numbers to a shipper box serial number / SSCC and in some cases a Pallet serial number / SSCC also.

Waymade were looking for a partner to provide them with a complete solution of data capturing of the relevant data matrix / barcodes for each packaging level, as well as the provision of serialisation / aggregation reports in the correct format for serialisation platforms.

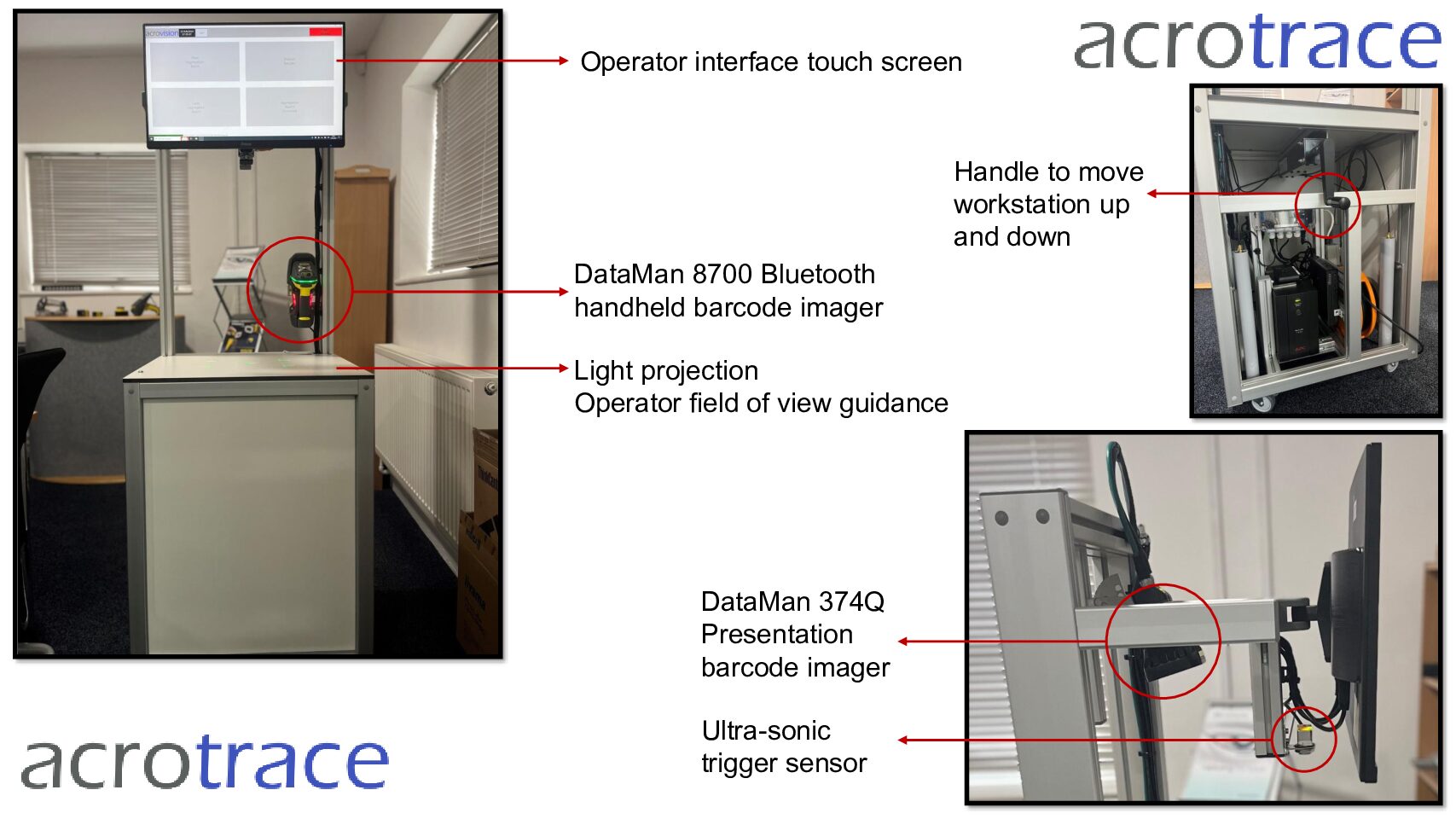

The data collection solution needed to be a bespoke mobile workstation to offer flexibility of use. Acrovision consulted with Waymade about their requirements and were able to offer a turnkey solution, namely Acrotrace.

Acrovision had previous experience of designing mobile data collection workstations but added the ability of height adjustment of the worktable to cater for different working heights.

The Acrotrace software created has the following functionality:

- Unique User ID and password control

- Access level control

- Ability to create / and edit product batch recipes.

This being the main setup for required scan quantities for a product - Run-time prompts and batch status data

- Product / batch look up

- Aggregation report creation – uploaded to Waymade host

- Report format selection

- Batch error reporting

The fixed position / presentation scanner selected was the Cognex DataMan 374Q, which is capable of scanning multiple codes in ‘bundles’ at extremely fast speeds, resulting in higher efficiency and productivity.

The handheld reader chosen was the Cognex DataMan 8700DQ which offers Bluetooth functionality for ease of use, thus allowing users to scan aggregation codes away from the main workstation itself when packaging pallets for shipment.

Waymade has found the Acrovision solution to be a fast, flexible and reliable solution, leading to improved operational efficiency for their packaging operations when aggregation is required. Ultimately providing a final automated report which can be imported directly into the serialisation systems they use.

Here, Simon is demonstrating Acrovision’s newest solution, Acrotrace, a turnkey barcode capture and aggregation system.