Description

End of line inspections have become a key focus within the Food, Drink and Tobacco Industries as retailers are becoming more stringent about quality compliance and good manufacturing practice. Incorrect labelling can result in poor customer satisfaction at best or at worst, hefty fines or Emergency Product Withdrawals (EPW).

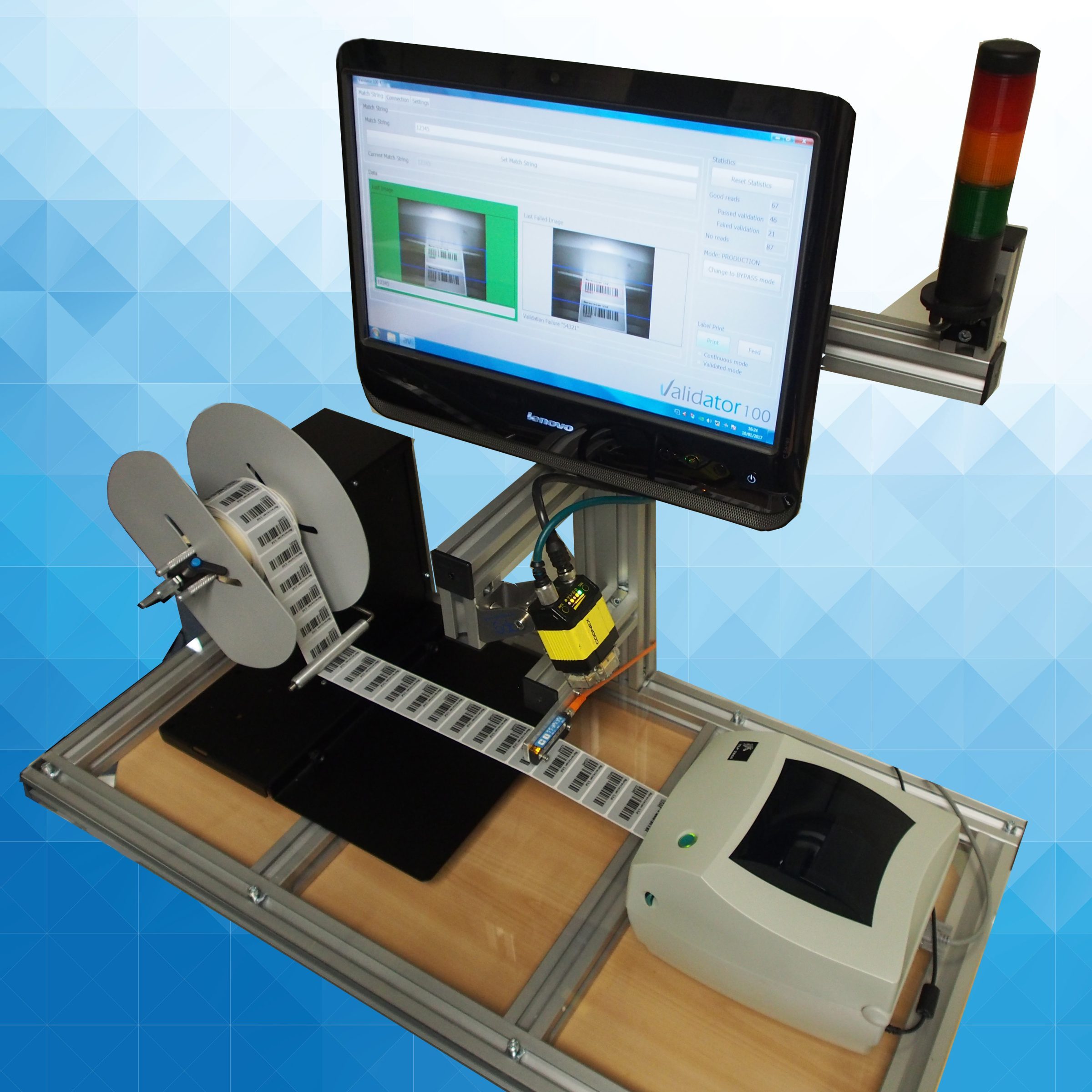

Acrovision has created a suite of in-line Package and Label Inspection Systems to monitor and control production lines; to ensure 100% correct product in the correct packaging with the correct data.

Not only can it validate correct and readable barcodes, but gives the user options of how the ‘master’ barcode is taught. The Validator 100 can be taught by a separate handheld barcode reader from a ‘menu sheet’, or from a simple press button mechanism, or even via a touchscreen PC, which then gives the user the ability to look at the images in real time and see ongoing performance statistics. The Validator 100 can guarantee you 3 things:

- Correct Barcode

- Missing Barcode

- 100% Inspection

For more information on the Validator 100, Contact Us!